Delivering cable security to renewables worldwide

15 years of experience

To make a difference in cable protection systems

Global Cable Protection was founded in the Netherlands in 2009 as CPNL/Dutch Cable Protection, by its current owner Ton Tuk. Following a period of research and development, together with our industry partners, we have developed functional, reliable and proven cable protection systems. We stayed true to our concept of cast iron products throughout the years and proved steadily the advantages of our systems via extensive empirical testing in cooperation with accredited testing facilities and universities. CPNL/Dutch Cable protection has evolved, and with growth comes change, and after 15 years the company has now restructured and rebranded to Global Cable Protection to better represent its’ global nature in supporting renewables worldwide.

Our Products

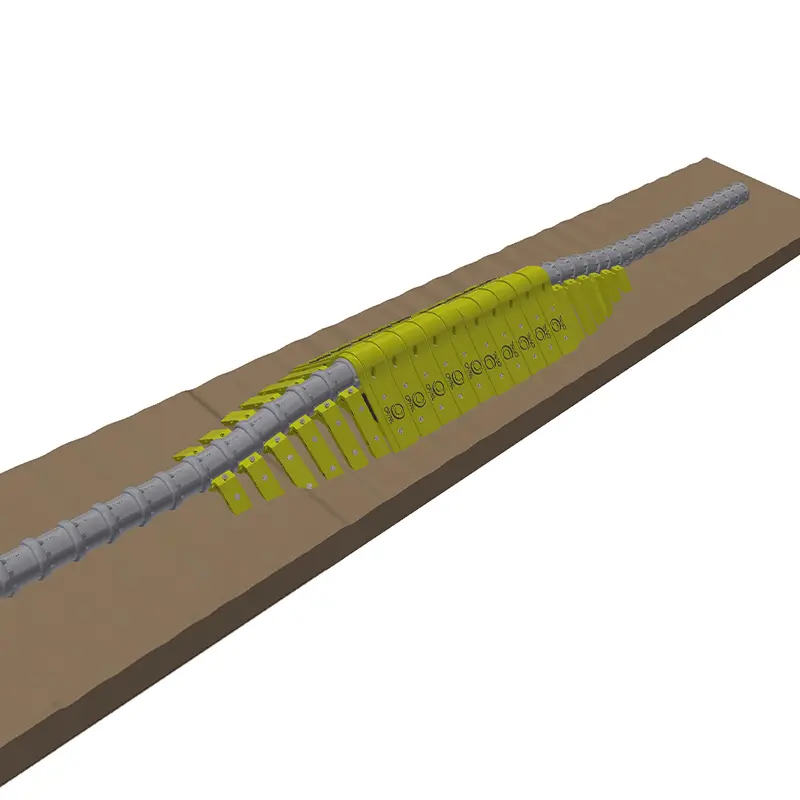

Subsea Cable Protection

Our standard range of Subsea Cable Protection Systems support cables from XXmm to XXmm. Our cast iron articulated ‘half shell’ design has been extensively tested and proven to be sufficient for use for a 25 Year life.

Global Cable Protection offer a truly boltless cast iron system.

Testing

As part of our development of our systems, we have completed various tests, including the dynamic simulation of a 25yr life cycle, performed independently at the university of Exeter.

Cable Protection Interface

Global Cable Protection have evolved their structure interfaces to accommodate ‘bolt on’ solutions using our core ‘half Shell’ articulated pipe. These interfaces allow the use of our articulated ‘half shells’ with I-Tubes, J-Tubes, Direct Flanges, Angled Annulus openings etc. Additionally we are capable of designing additional interface adaptors, for example for existing J-Tube bellmouths, where cable replacement takes place.

Cable Hang-Offs

We have designed and produced bespoke hang off devices for clients on various renewables projects. Our systems are designed to suit the exact needs of the client for the project. These are designed in house, and verified by external companies prior to production within our local supply chain.

Cable Crossing Systems

Global Cable Protection have developed a cable crossing system, which is assembled and deployed by the Cable lay Vessel during cable installation. This allows cable installers to avoid the need for preparatory works to guarantee separation at crossings, and provides instant protection during lay, thus avoiding guard vessels etc. The system is designed for a 25 yr submerged lifetime, and utilises DNV-GL certified polymer materials for this lifetime. These crossings also allow recovery of the system at end of life, which can be beneficial for project environmental constraints.

Cable Repair Solutions

Over recent years the renewable industry has experienced many occurrences of Cable damage due to failings in Cable Protection design/deployment. Global Cable Protection have been involved extensively in the design of repairs for other manufacturers systems, and together with our industry partners have devised various ‘band aid’ solutions for other manufacturers systems, allowing our clients to make decisive, timely and cost effective interventions when these issues are discovered.

Cable Replacement Solutions

Where a faulty cable is to be replaced, the Cable Protection Systems and Hang-Offs will normally also be replaced. Our experience has shown that developers are unlikely to replace a broken CPS with one from the same manufacturer, as this presents an increased potential risk of re-occurrence. Global Cable Protection have assisted clients with their replacement projects, sharing our wealth of knowledge on the topic and assisting them with their planning.

Why Choose Us

Known for its no nonsense logical approach to designing solutions

CPNL supports its clients challenges, optimising systems to last an offshore asset lifetime.

- Optimisation specialists thanks to rich experience in O&M repair projects.

- Simple, reliable, proven solutions.

- Designs certified by DNV-GL for unrestricted offshore use.

Frequently Asked Questions

It’s important to us that our clients feel fully informed and confident when working with us. That’s why we’ve made an extensive list of past clients’ questions along with answers from our experienced team. Browse through the information below, and if you have a question that isn’t included here, feel free to reach out to us today.

What types of cable protection systems are available?

Cable Protection Systems can be roughly divided into three main categories;

- Solutions for monopile entry (ie through a monopile aperture, also referred to as J-tubeless)

- Solutions for I-/J-tube entry

- Solutions for seabed protection – such as areas of rock outcrop or where soils are not trenchable.

There are then subcategories for 1 and 2 including ‘bend stiffeners’ and ‘bend restrictor’ solutions, not to mention solutions from different materials. Selecting an appropriate Cable Protection System for your site specific circumstances may not be as simple as you’d first expect.

What makes a CPNL cable protection system different than other CPS?

Our systems are the result of several years of continuous refinement, based upon feedback from internal and external users, all of which has led to the CPNL product range available today.

Our systems are designed to be simple and effective, and take into account the entire life cycle of the project.

Feedback from our clients shows us that in general the advantages of our products are not always obvious until they are used in practice. It is starts with “aha”, and from there things go exactly as planned with no surprises. Assembly, installation and retrieval of the cable and CPS is kept simple and quick, thanks to our truly boltless solution within the dynamic zone.

All lessons learned from O&M projects have been incorporated into the designs we offer today. CPNL products function as designed, our life cycle assessments are based on empirical test results, and our systems have been proven in real O&M scenarios to be truly ‘diverless’ and maintenance-free and without need for additional stabilisation after installation.

CPNL has a long-term vision regarding cable protection solutions with DNV-GL Design Certification, representing all individual CPS components, to verify unrestricted offshore use of its CPS for a minimum duration of 25 years, with a safety margin of 5. In order to achieve this certification we designed and implemented empirical testing of our systems, based on worst case scenario conditions, the result is a proven simple system, easily installed and retrieved without divers which is unique in the market.

What is the range of CPNL's articulated pipes?

CPNL offers a broad range of inner diameters articulated pipes, made of a high quality ductile cast iron in accordance with DIN-1563 EN-GJS-400-15.

A coated version of the articulated pipe is also available, which is suitable for poor visibility in water and to avoid oxidation and corrosion pitting completely.

The range starts at 30mm inner diameter all the way up to 300mm inner diameter with an effective length of 333mm. Upon client request, CPNL also offers 500mm effective length.

All other cable related aspects, such as MBR, will be included in the design.

What is the product warranty on CPNL products?

CPNL offers, as a standard, 25 years product warranty for all its systems.

We are also uniquely able to offer an insurance backed 15yr warranty which covers the removal and reinstallation of a customers cable with a supplied replacement should the cable fail within the area protected by the CPS. CPNL is the first supplier with this unique extended product warranty, which we are able to offer based on the confidence gained by our DNV-GL Design Certificate.

Please contact our commercial team for further details of this option.

What is a subsea Cable Protection System (CPS)?

As the name suggests Cable Protection Systems (CPS) protect subsea power, data and telecommunication cables within a maritime environment against various factors that negatively impact on the cable lifetime. Cable Protection Systems are usually applied in the dynamic zone, which is from the point of cable entry to the structure down to a designated trench point, to prevent excessive wear due to dynamic influences such as current, and spans.

Our CPS has also been used for other purposes, such as protecting water pipes between islands and the mainland.

Why is cable protection necessary?

An offshore project has an expected lifespan objective of 25 years or more. A cable in an offshore environment such as that found in renewables will be exposed to all kinds of influences, which impacts the product lifetime of the cable.

In the past the following evaluation was made to meet this 25-year objective:

- Apply more armouring to the cable, which leads to considerably higher purchase prices for the cable; or

- Apply Cable Protection Systems at a lower expense.

Offshore windfarm developers have opted for the installation of Cable Protection Systems based on this being the more cost effective solution. Proper attention should be paid to determining what is needed from a CPS to fulfil project requirements.

Not all CPSs are suitable or applicable for your cable assets/site conditions. The more specific you are as a developer/contractor, based on your assessment, the better the results will be translated into achieving the 25-year life span objective.

Though careful selection of CPS developers/contractors can ensure that their projects do not suffer costly downtime/repairs during the project O&M phase, which could have been avoided by careful procurement.

Why should you opt for CPNL?

What makes CPNL's cable protection systems the most suitable for offshore projects?

CPNL’s cable protection systems are designed to meet the specific needs of offshore projects, providing reliable and long-lasting protection in even the harshest environments. We take a careful and analytical approach to our design process, ensuring that our solutions are effective, efficient, and tailored to each client’s needs.

What is CPNL's approach to providing effective solutions?

At CPNL, we take a careful and collaborative approach to providing effective solutions to our clients. We work closely with them to understand their needs and requirements, and use the latest experiences and materials to provide solutions that are reliable, efficient, and long-lasting.